Shanghai Snowhorse M&E Equipment Co., Ltd. as the first level distributor which authorized by INPRO/SEAL and the top sales distributor of China, was awarded the Eagle cup in 2014. Mr. MARK, President of INPRO/SEAL global present the reward in person.

For INPRO/SEAL

products, we have not only professional sales staff, but also strong

after-sales service capabilities. Our company can provide door-to-door

inspection, measurement and best proposal. We can also provide door-to-door

installation and commissioning after sales. Up to now, we have successfully provided technical upgrading for a

number of world-class enterprises, and completely solved site leakage problems.

If you has any leakage problems with your

equipment, please feel free to contact us, we will provide you the best

solution.

At the start of project, industrial users usually pay great attention to the

quality of the bearing, and often designate equipment manufacturers to adopt

high-quality bearing brands such as SKF, FAG, NTN, etc., and use high-quality

lubricating oil recommended by manufacturers to ensure the service life of the

bearing, so as to ensure stable operation of the equipment and reduce

maintenance. Temperature and vibration probes will also be installed at key

bearings to monitor bearing performance.However, the oil seal is often ignored as a barrier to isolate

moisture and dust in the air from the lubricating oil. Up to now, many

equipment manufacturers still use the lip seal and ordinary labyrinth oil seal,

but these two oil seals have obvious shortcomings, which cannot prevent the oil

from being polluted by moisture and dust in the air in the long-term use. Statistics

from bearing manufacturers show that 74% of bearing failures are caused by

contaminated oil that does not provide good lubrication.

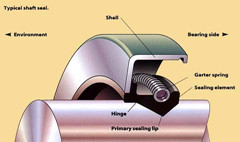

Before the invention of INPRO oil seals,

protective bearings were normally sealed with contact skeleton seals and

non-contact common labyrinth seals. The skeleton oil seal will leave carbides

on the contact surface of the shaft and cause wear to the shaft. Its life is

usually 3000 hours. It cannot be replaced timely after losing the sealing

function. And as a contact seal,

need to consume shaft power, friction generated heat will be transmitted to the

lubricating oil and bearings and affect the lubrication effect. According to statistics, each contact seal consumes an average of 147

watts of energy. Thus it can be seen that the skeleton seal has been

unable to meet the requirements of modern industry for high reliability and

continuous economic operation of process equipment.

Lip Seal Ordinary Labyrinth

Seal

The ordinary labyrinth oil seal is

non-contact, which does not cause wear to the shaft and does not consume the

shaft power. However, it cannot prevent the moisture and fine dust in the air

from entering the bearing box, nor can it prevent the oil mist from evaporating

into the air. The water content of lubricating oil has great influence on

bearing life. Experiments by NASA have shown that when the water content in the

lubricant increases, the life of the bearing decreases rapidly. See table following.

INPRO oil seal non - contact, non - wear

labyrinth seal provides permanent protection for bearings. INPRO oil seal is

made up of moving ring and stationary ring. During operation, the moving ring,

stationary ring and VBX O ring interact to prevent the loss of lubricating oil

in the bearing box and the foreign body outside the bearing box. Its unique design

makes it impossible for moisture and dust from the air outside the bearing box

to enter the bearing box. The actual service life of bearings sealed with INPRO

oil is usually 3 to 5 times longer than that of bearings sealed with normal oil

INPRO oil seals were invented and patented by

INPRO SEAL founder David Orlowski in 1977 (patent no. 4,022,479). They were

originally used in chemical process pumps and fully enclosed air-cooled motors. Its superior performance was unanimously

praised by customers, and soon almost all industrial rotating machinery used

INPRO oil seals. Up to now, INPRO oil seals have become the

standard configuration of most ANSI, ISO and API pump manufacturer, such as

Goulds, Flowserve, Sulzer and Union, etc. INPRO oil seals are also standard

configuration of IEEE-841 manufacturers such as Baldor, GE, Teco, Siemens,

Toshiba and Emerson. INPRO also provides oil seals to turbine, gearbox, coal

mill, fan and paper mill , such as Elliott, Terry, and CE Raymond.

Now the local

equipment manufactures start to use INPRO seals to improve their product

quatity in China, such as Sulzer, Deep Blue Pumps,Great Ebara Pump,Flowserve Pumps,Teco Motor(Suzhou).

INPRO

oil seal is the only non-contact labyrinth oil seal in the world that is

waterproof to steam and dust. Its stable and long-term bearing protection

performance has gradually replaced skeleton oil seal and common labyrinth oil

seal in various industrial fields. Its integral and split design can be applied

to shafts from 16mm to 2750 mm. INPRO oil seals are usually made of copper.

According to customer requirements, INPRO oil seals made of stainless steel,

titanium, aluminum alloy and other materials can also be provided. The

coefficient of thermal expansion of plastic is about 9 times that of copper,

and it will expand by 0.33mm after a temperature rise of 70oC, which will lead

to a decrease in sealing performance. Therefore, it is not used for INPRO. For

customers who use INPRO oil seals, the service life of the bearings is

prolonged, thus reducing the maintenance times of the equipment, reducing the

equipment damage caused by the bearing damage, increasing the reliability of

the equipment, and the non-contact design reduces the energy consumption, so

80% of customers choose INPRO oil seals to protect their bearings. INPRO oil

seal structure varies from simple to complex, and its design is very diversified.

We can change our design according to the requirements of users, thus meeting

the needs of user equipment.

Inpro/Seal Design Variations

|